Expanding Capability Without Compromising Precision

Case Studies

AFS150 Development

Automotive Industry

An automotive manufacturing client approached Elite Interfaces seeking to dramatically improve their production throughput.

They wanted to explore the feasibility of increasing their panel sizes to accommodate more products during the design and testing phases, whilst also automating their rear rail movement to significantly reduce fixture changeover times and enhance operational efficiency.

Elite faced two fundamental obstacles in meeting these ambitious requirements:

- The standard AFS150 system's Unit Under Test (UUT) area was specifically configured for the customer's existing "standard" panel dimensions, offering no capacity for the larger formats they envisioned

- The standard AFS150 featured manual rear rail adjustment - a time-consuming process that was incompatible with the customer's goals for rapid fixture transitions

Elite's Solution

Our engineering team didn't simply modify the existing system; we evolved it entirely. Working closely with the customer's specifications and operational requirements, we developed a completely new revision: the AFS150XW.

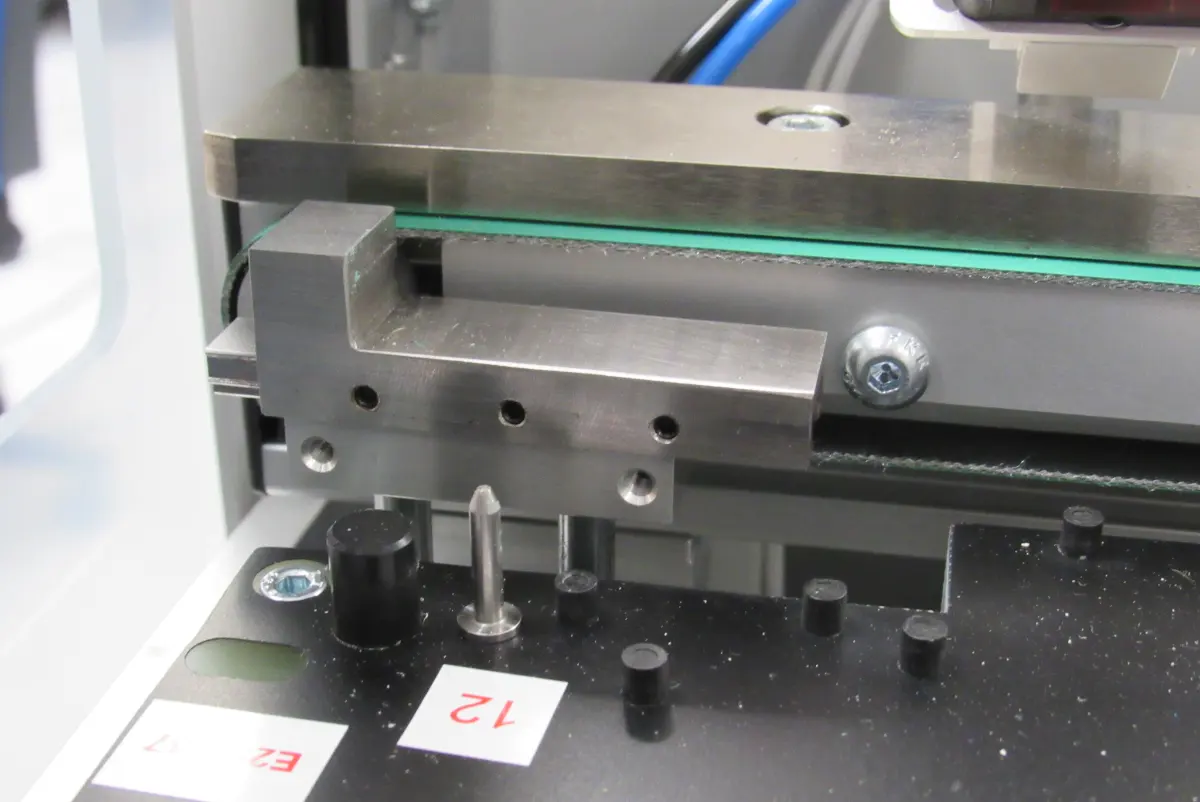

- We expanded the UUT testing area capacity by increasing the overall system width by 100mm, creating sufficient space to accommodate substantially larger panels whilst maintaining testing accuracy and reliability

- Our design engineers created an innovative adjustable board stop mechanism, providing even greater flexibility in UUT positioning and further maximising the available testing area

Result

The result was a transformed testing capability that not only met the customer's immediate throughput objectives but positioned them for continued growth, demonstrating Elite's commitment to developing solutions that anticipate our clients' evolving needs rather than simply addressing today's challenges.

Flash Programming · in-Circuit Test · Functional test

No other company provides a wider range of test solutions for PCB manufacturers than Elite Interfaces.

Since 1986, high volume electronics manufacturers have come to us for expert analysis, design and build of turnkey test solutions for all major test platforms.

If you need a test solution for the end of your production line for panellised boards or microcontroller boards, Elite Interfaces is the one stop shop, with an unsurpassed reputation for commitment, quality and customer service. Contact us now to discuss your current test solution challenge.