From Manual Operation to Full Robotic Automation

Case Studies

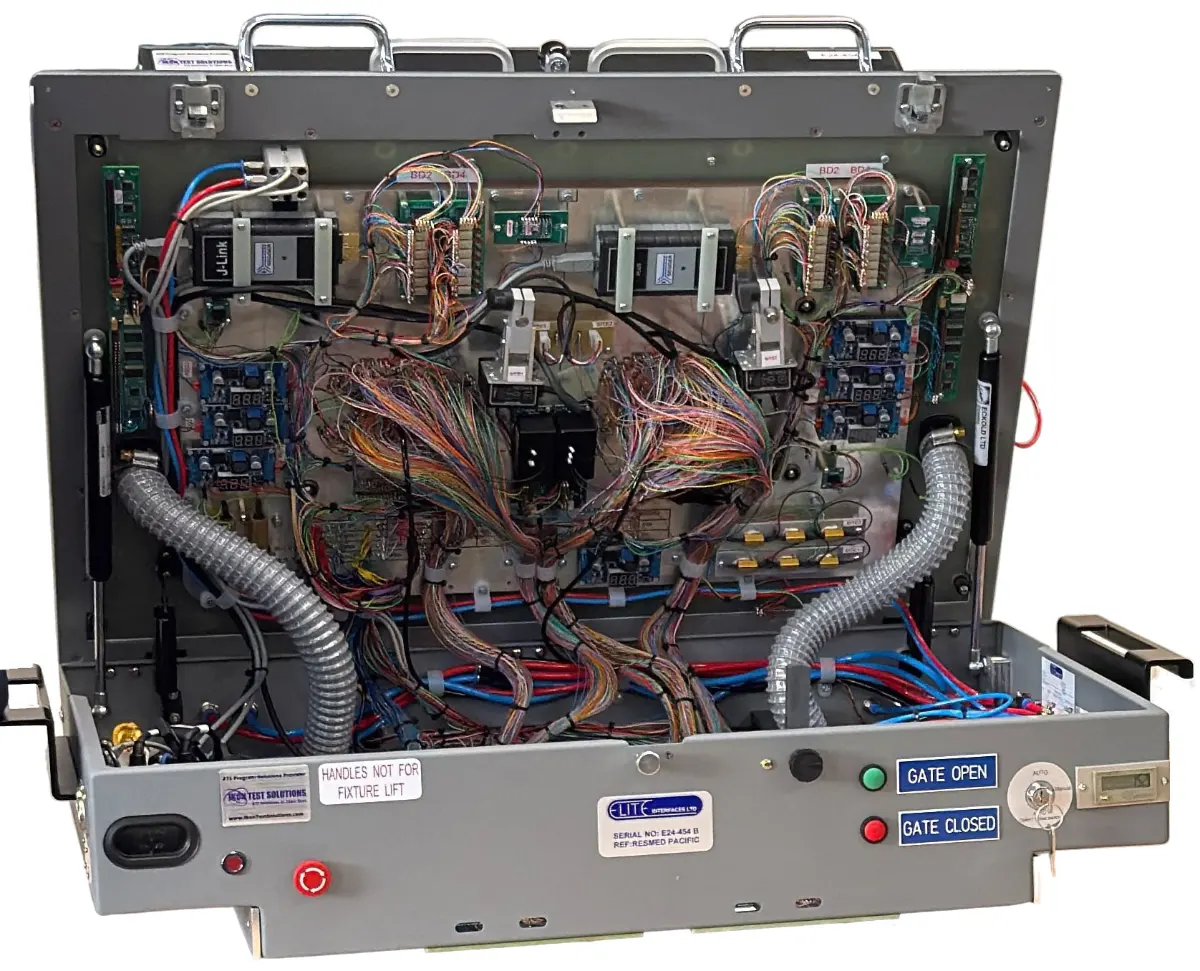

ICT and Functional Combined Fixture

Medical Industry

A medical industry client faced a complex testing requirement that demanded both innovation and precision.

They needed a sophisticated test fixture and accompanying software capable of performing both In-Circuit Testing (ICT) and Functional testing within a single, integrated system—all whilst meeting stringent time constraints critical to their production schedule.

Adding further complexity, the customer required versatility in the fixture's top hat assembly, with the capability to operate in either manual or fully automated modes depending on production demands.

Obstacles

Elite confronted several significant technical obstacles:

- The finite dimensions of the fixture target type severely limited the physical space available for integrating all the necessary testing hardware and components

- The top hat design needed to accommodate automatic opening and closing mechanisms whilst incorporating comprehensive safety features—a challenging engineering requirement in such a constrained space

Elite's Solution

Our multidisciplinary team approached this challenge with characteristic thoroughness, developing solutions that exceeded the customer's expectations:

- We meticulously re-engineered internal components, reducing their physical footprint wherever possible whilst simultaneously enhancing their performance and reliability—a testament to Elite's commitment to innovation without compromise

- Our engineers developed enhanced connectivity solutions alongside sophisticated software improvements, ensuring seamless integration of both testing methodologies within the customer's operational framework

- We designed and implemented a bespoke automatic opening and closing system for the fixture, complete with comprehensive safety protocols to protect both operators and the sensitive medical components being tested

- Taking the solution even further, we introduced advanced hardware and software controls that enabled a robotic arm to autonomously load and unload Units Under Test into the fixture—transforming what began as a manual process into a fully automated testing operation

Result

The result was a transformed testing capability that not only met the customer's immediate throughput objectives but positioned them for continued growth, demonstrating Elite's commitment to developing solutions that anticipate our clients' evolving needs rather than simply addressing today's challenges.

Flash Programming · in-Circuit Test · Functional test

No other company provides a wider range of test solutions for PCB manufacturers than Elite Interfaces.

Since 1986, high volume electronics manufacturers have come to us for expert analysis, design and build of turnkey test solutions for all major test platforms.

If you need a test solution for the end of your production line for panellised boards or microcontroller boards, Elite Interfaces is the one stop shop, with an unsurpassed reputation for commitment, quality and customer service. Contact us now to discuss your current test solution challenge.